Multi jet fusion also falls in the hardener category. First, the

printer deposits a layer of material onto a platform. Then it drops

additional material at thirty million drops per second to build the

object, layer by layer. In some cases, the printer builds multiple

objects at a time. Finally, it fuses the materials and then heats and

cools the object exactly where it needs to make a smooth-edged,

well-defined object.

HP provides this technology to aerospace, automotive,

medical, dental, life sciences, and a variety of other industries.

What material can you use? HP says anything. Companies work

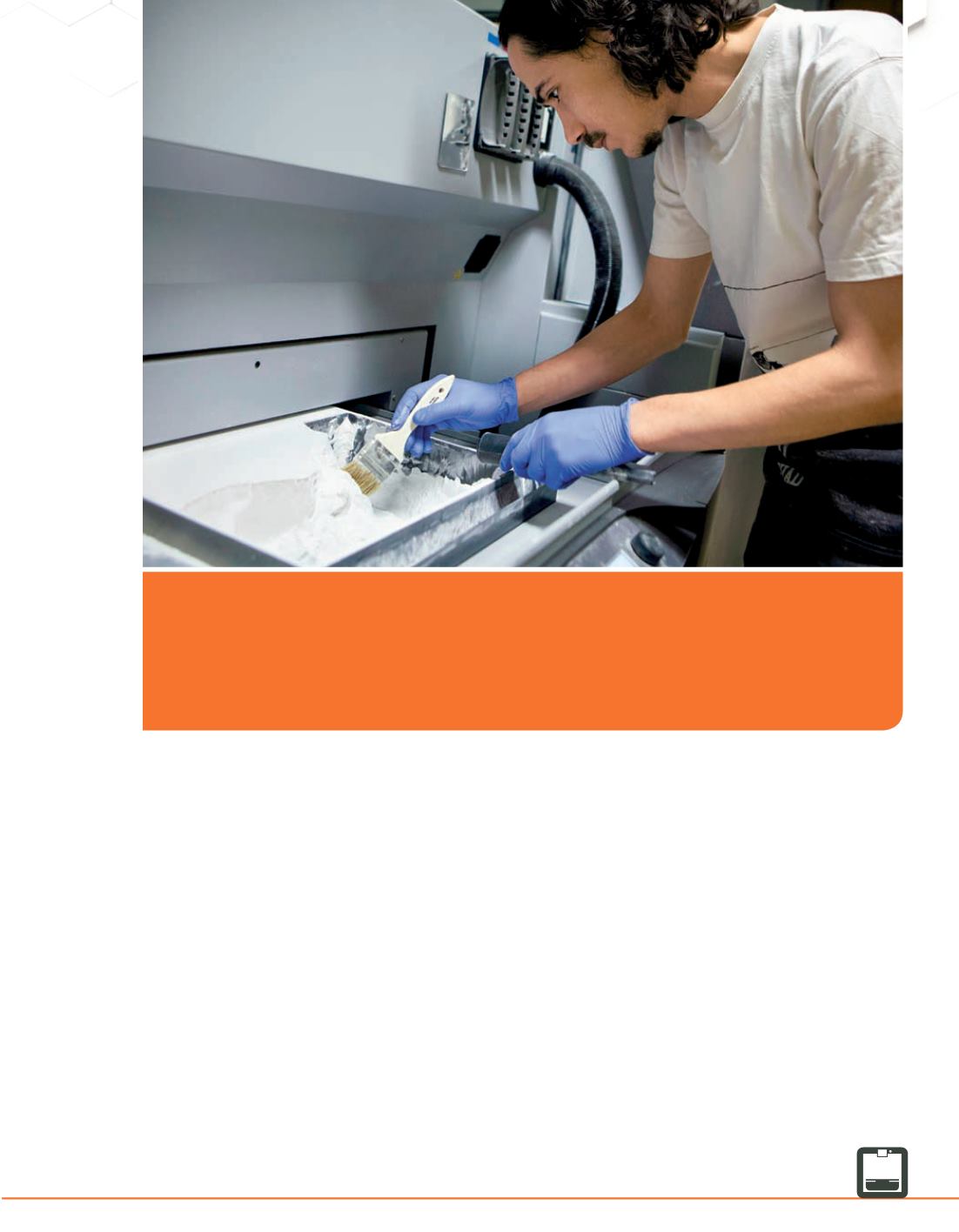

SLS technology 3D prints objects in a bed of powdered material. A laser beam sinters

(heats) or melts certain areas of the powder to build the object layer by layer. As it

is printed, the rest of the powder supports the piece. Manufacturers then use an air

nozzle, a sand blaster, or a simple brush to remove the powder support when the

piece is finished.

21

H O W I T W O R K S